STAINLESS STEEL STRIP

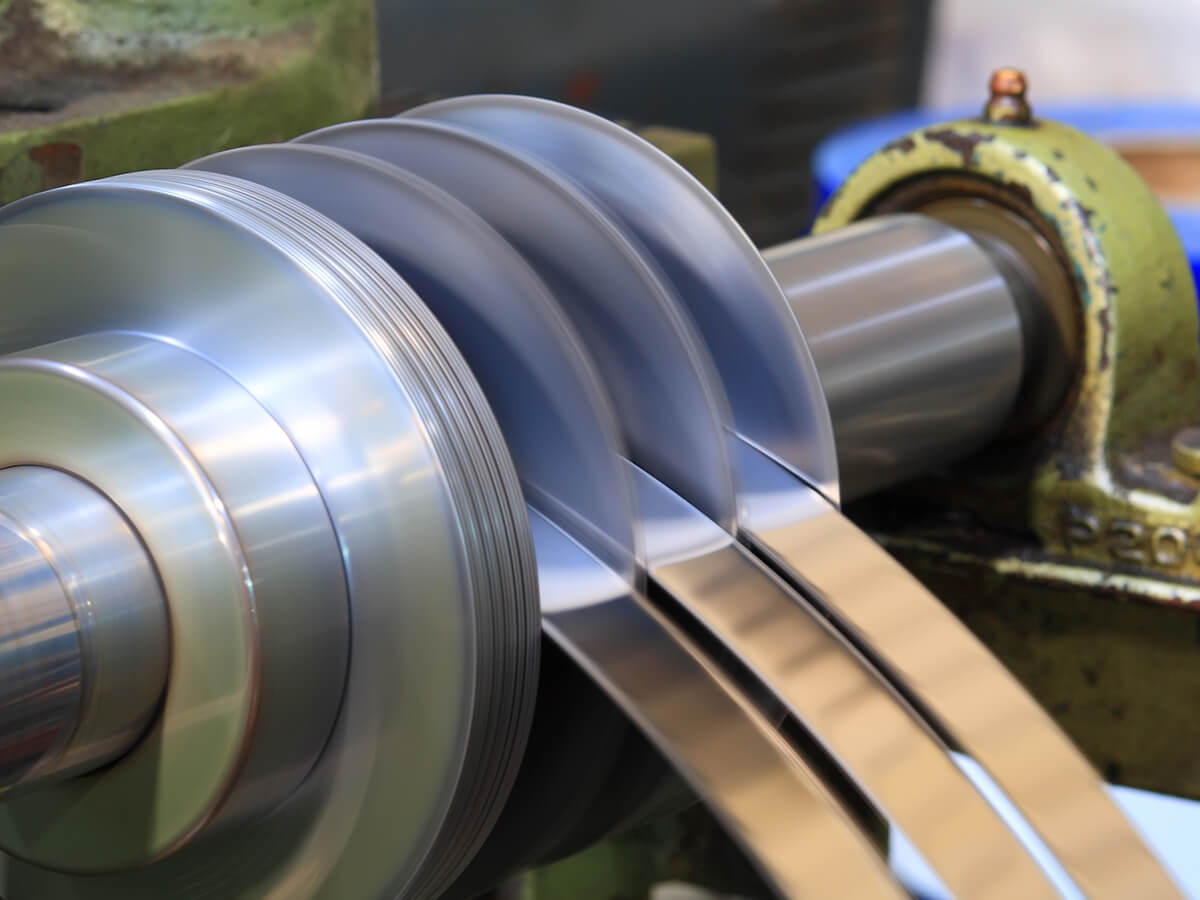

- Product type: Cold rolled stainless steel precision slitting

- Product specifications: ASTMA240/A480,JIS4305,EN102043.1,

EN10028-7/10088-2 - Steel Grade:304(1.4301)/304L(1.4307)/316(1.4401)/316L(1.4404)

/430(1.4016)/409(1.4512)/439(1.4510)/201(1.4372)/202(1.4373) - Surface finish: 2B/NO.3/NO.4/NO.5/HL/SB

- Production thickness: 0.10~2.00mm

- Production width: 4mm~650mm

- Coil inner diameter: 300mm/400mm/508mm

| COLD ROLLED STAINLESS STEEL PRECISION SLITTING | ||||||

|---|---|---|---|---|---|---|

| SURFACE FINISH | STEEL GRADE | THICKNESS(MM) | MOTHER COIL WIDTH(MM) | |||

| 650 | 1219 | 1250 | ||||

|

2B NO.3 NO.4 NO.5 HL SB |

304(1.4301) 304L(1.4307) | 0.10~0.20 | * | |||

| 0.30~3.00 | * | * | ||||

|

316( 1.4401) 316L(1.4404) | 0.30~0.60 | * | ||||

| 0.70~3.00 | * | * | ||||

| 430(1.4016) | 0.20~3.00 | * | * | |||

|

409(1.4512) 439(1.4510) | 0.30~2.00 | * | * | |||

|

201 (1.4372)(Ni: 1%) 202 (1.4373)(Ni: 4%) | 0.30~2.00 | * | * | |||

| BA | 201 (1.4372)(Ni:1%) | 0.20~1.00 | * | * | ||

| 304(1.4301) | 0.10~0.20 | * | ||||

| 0.25~2.00 | * | * | ||||

| 430(1.4016) | 0.25~2.00 | * | * | |||

STAINLESS STEEL STRIP INTRODUCTION

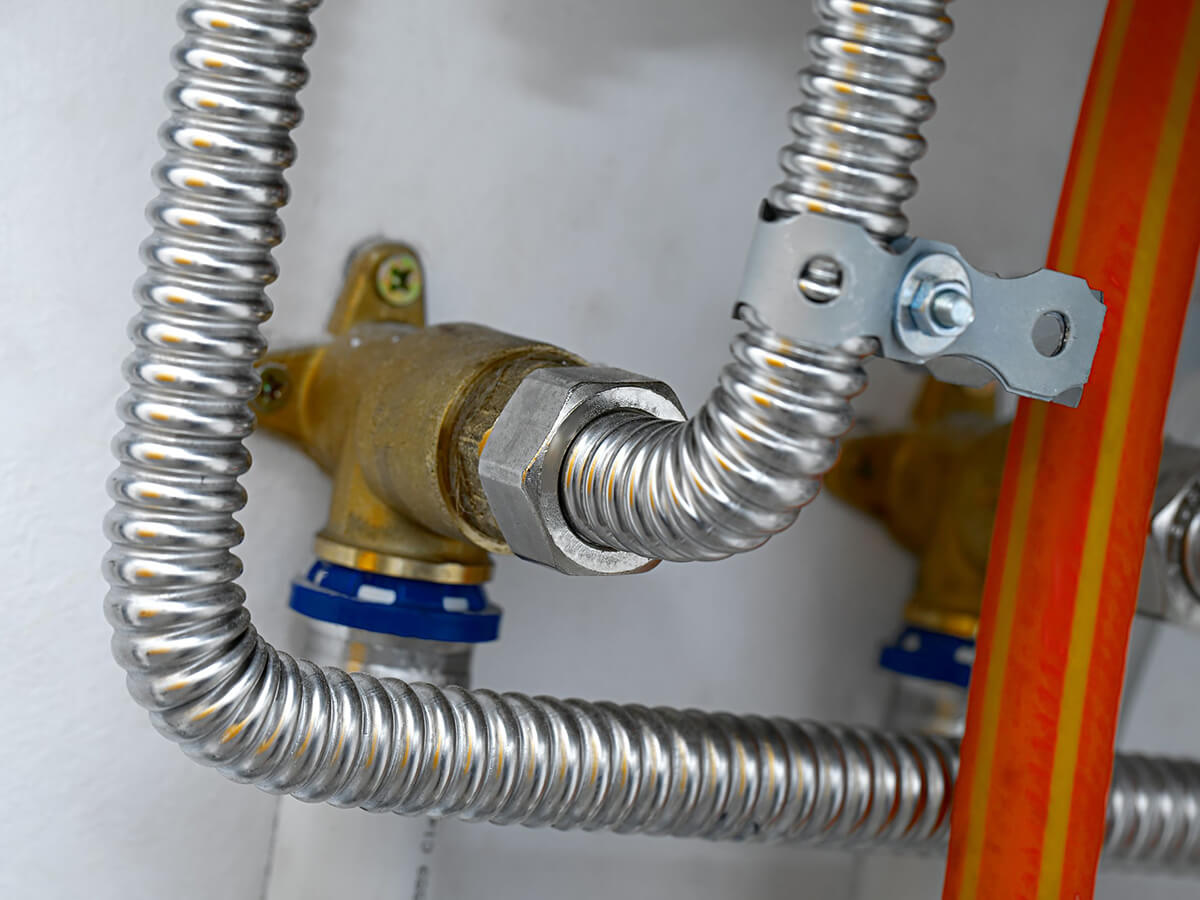

Stainless steel strip is a precision material produced by slitting stainless steel coils into narrow widths. With excellent corrosion resistance, heat resistance, and mechanical strength, stainless steel strip is widely used across industries such as electronics, automotive, home appliances, construction, medical devices, and precision engineering. Thanks to its consistent thickness, stable dimensions, and superior formability, stainless steel strip is ideal for stamping, bending, welding, and other secondary processing applications.

Common stainless steel strip grades include 304, 316L, 301, and 430.

- 304: The most widely used grade, offering balanced corrosion resistance and formability, making it suitable for kitchenware, consumer goods, and general industrial use.

- 316L: Enhanced with molybdenum for superior resistance to acids, alkalis, and chloride environments. It is the preferred choice for marine, chemical, and medical industries.

- 301: Known for its high strength and excellent elasticity, making it widely used in springs, connectors, and precision electronic components.

- 430: A ferritic stainless steel with lower cost and good heat resistance, commonly applied in appliance structures and general building materials.

Surface finishes can be tailored to different applications, including 2B, BA, No.4, HL (Hairline), and Mirror finish. For example, BA’s bright reflective surface is often used in premium kitchenware and household appliances, while No.4 and HL finishes are popular in decorative panels, construction materials, and interior design for their modern and elegant appearance.

In terms of specifications, Genn-Hann Stainless is equipped with multiple precision slitting lines, capable of supplying stainless steel strips with thicknesses ranging from 0.1mm to 3.0mm and widths as narrow as 4mm. This flexibility allows us to deliver customized solutions that minimize material waste, improve manufacturing efficiency, and meet strict dimensional tolerances required in precision industries.

With strict quality control and a stable monthly supply, Genn-Hann Stainless not only provides stainless steel strips in international standard specifications but also offers tailor-made solutions to meet unique customer requirements. Our stainless steel strips are trusted by industries manufacturing electronic components, automotive parts, springs, fasteners, and precision hardware, delivering consistent performance and reliability.

Product Addition Service

- Polishing Method: Oil polishing and dry polishing

- can do main side polishing/both side polishing/backpass

- can do PE/PVC FILM/ LASER FILM/PAPER INTERLEAVED

- Coil width can be customized according to customer size