Table of Contents

In the global industrial landscape, Stainless Steel Coil is often referred to as the “backbone” of manufacturing. From the sleek panels of a high-end kitchen to the heavy-duty components of a chemical refinery, the quality and specification of the stainless steel coil used can make or break a project’s success.

As a professional in the industry, whether you are a procurement manager, an engineer, or an international trader, understanding the nuances of stainless steel coils is essential. In this comprehensive guide, GENNHANN STAINLESS STEEL provides an in-depth look at types, finishes, manufacturing processes, and key factors to consider when sourcing stainless steel coils for your business.

1. What is Stainless Steel Coil?

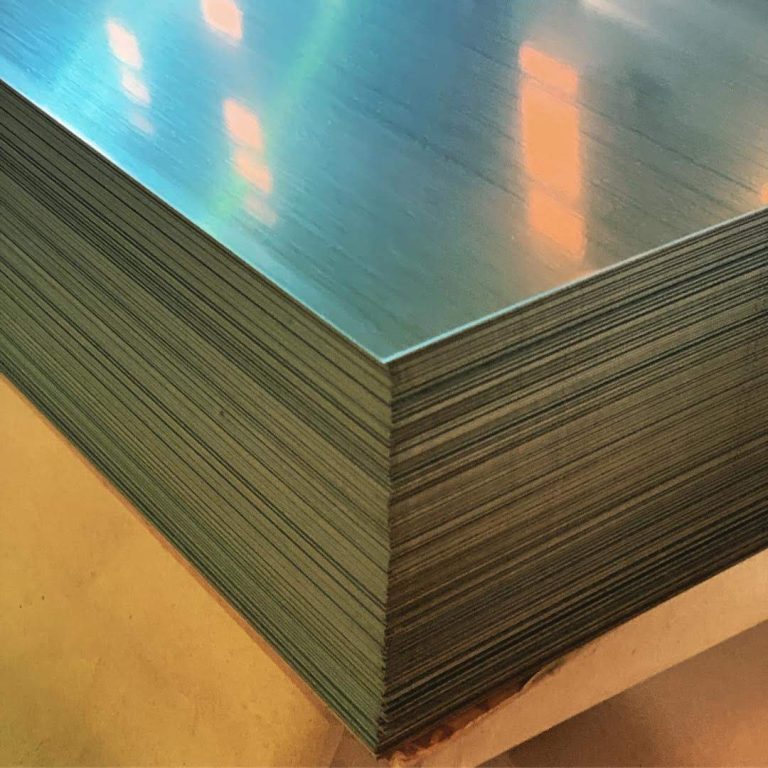

A stainless steel coil is a finished steel product, such as a sheet or strip, that has been wound after rolling. Based on the production method, it is categorized into Cold Rolled (CR) Stainless Steel Coil and Hot Rolled (HR) Stainless Steel Coil.

The primary appeal of stainless steel in coil form lies in its continuous length, which allows for high-speed automated processing in manufacturing plants, reducing waste and increasing efficiency compared to individual sheets.

2.Material Grades: Choosing the Right Alloy

The most critical decision in sourcing is selecting the correct grade. Each grade offers a different balance of corrosion resistance, strength, and cost.

The 300 Series: Austenite (The Most Popular)

- Grade 304: The “All-Rounder.” Known for its excellent corrosion resistance and formability. It is the standard for food processing, kitchenware, and architectural applications.

- Grade 316/316L: The “Marine Grade.” Contains molybdenum, providing superior resistance to chlorides and marine environments. Essential for chemical processing and pharmaceutical equipment.

The 400 Series: Ferrite & Martensite (The Cost-Effective Choice)

- Grade 430: Offers good corrosion resistance and formability but is less resistant to corrosion than the 300 series. It is magnetic and commonly used for appliance trims and automotive parts.

- Grade 410/420: Hardenable grades used for cutlery and high-strength industrial components.

The 200 Series: Manganese-Based (The Budget Option)

- Grade 201: Lower nickel content makes it cheaper, but it is less resistant to corrosion. Suitable for indoor decorative purposes or mild environments.

3.Technical Specification Table

The Core Data for Your Procurement

Feature | Specifications & Availability |

Material Grades | 304, 304L, 316L, 321, 430, 201, and high-performance alloys. |

Surface Finish | No.1,2B, BA, , No.3,No.4, HL. |

Thickness (CR) | 0.3mm – 3.0mm (Cold Rolled) |

Thickness (HR) | 2.5mm – 6.0mm (Hot Rolled) |

Standard Width | 1000mm, 1219mm, 1500mm (Custom Slitting Available) |

Standard | ASTM A240, JIS G4305, EN 10088 |

Coil ID | 300mm / 400mm / 508mm / 610mm |

4.Understanding Surface Finishes

The surface finish of a stainless steel coil is not just about aesthetics; it also affects how the material performs in specific environments.

No.1 Finish (Hot Rolled)

Produced by hot rolling, annealing, and descaling. It has a dull, rough, silver-white appearance. Primarily used in industrial applications where surface smoothness is not a priority, such as structural parts.

2B Finish (Cold Rolled, Dull)

The most common cold-rolled finish. It is smooth and slightly reflective but not like a mirror. It provides an excellent base for further processing or for use in food and medical equipment.

BA Finish (Bright Annealed)

Processed by bright annealing in a controlled atmosphere. It is highly reflective and mirror-like, perfect for high-end appliances and decorative trims.

No.4 & Hairline (Brushed/Polished)

Characterized by short or continuous polishing lines. These finishes are excellent for hiding fingerprints and scratches, making them ideal for elevator interiors and restaurant equipment.

STAINLESS STEEL SURFACE FINISH

5. The Manufacturing Process: From Slab to Coil

Understanding how your coil is made helps you appreciate the quality differences between suppliers.

- Melting and Casting: Raw materials (Iron ore, chromium, nickel, etc.) are melted in an electric arc furnace and cast into slabs.

- Hot Rolling: Slabs are heated and passed through large rollers to reduce thickness, resulting in Hot Rolled Coils (No.1).

- Annealing and Pickling: The steel is heat-treated (annealed) to relieve internal stresses and bathed in acid (pickling) to remove scales.

- Cold Rolling: For thinner and smoother coils, HR coils are rolled at room temperature. This increases strength and improves surface quality.

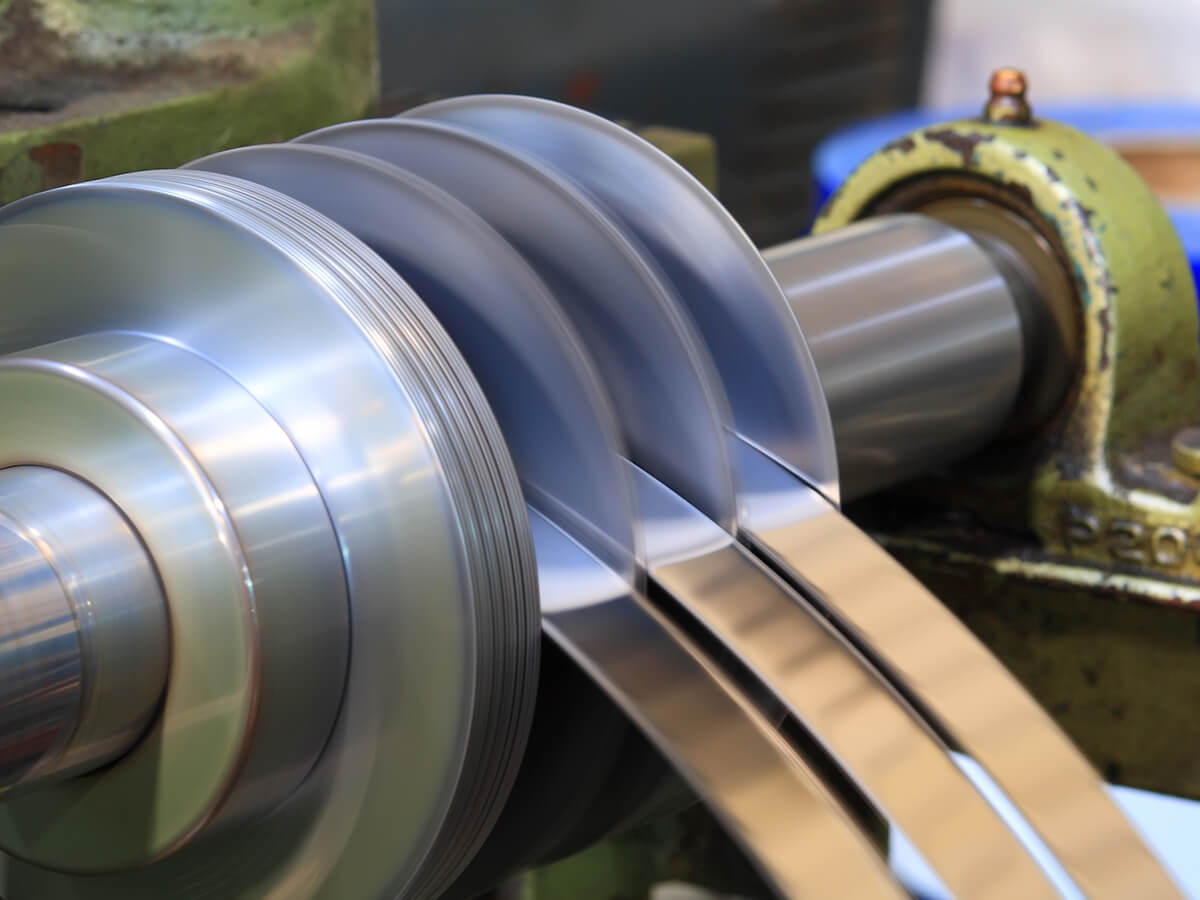

- Slitting and Cutting: Large “Mother Coils” are slit into “Strip Coils” according to the customer’s required width.

6. Key Processing Services: Adding Value to Your Order

At GENNHANN STAINLESS STEEL, we don’t just supply raw materials; we provide solutions.

- Precision Slitting: Using advanced machinery to cut wide coils into narrow strips with tolerances as tight as ±0.1mm.

- Cut-to-Length: Converting coils into flat sheets of any specified length.

- Surface Protection: Applying PE or Laser PVC film to protect the surface from scratches during fabrication and transport.

- Paper Interleaving: Placing paper between layers of the coil to prevent friction damage, especially for BA or Mirror finishes.

7. Sourcing Criteria: What Every Procurement Officer Should Check

When you receive a quote for “Stainless Steel Coil Price per Ton,” don’t just look at the number. Check these four pillars:

A. Mill Test Certificate (MTC)

A genuine supplier must provide an MTC (EN 10204 3.1) that details the chemical composition (Nickel, Chromium, Molybdenum content) and mechanical properties (Yield strength, Tensile strength, Elongation).

B. Dimensional Tolerance

Inconsistent thickness across a coil can damage your stamping dies or laser cutters. Ensure the supplier follows international standards like ASTM A240 or JIS G4305.

C. Packaging for Export

Coils are heavy and susceptible to moisture during sea freight. Look for:

- Eye to Sky vs. Eye to Wall: Depending on your unloading equipment.

- Waterproof Paper & Metal Strapping: To prevent rust and physical damage.

- Wooden/Steel Pallets: Essential for safe forklift handling.

D. Lead Time and Logistics

Time is money. A supplier with a stable stock of common grades (304/316L) can significantly reduce your production downtime.

STAINLESS STEEL MATERIAL QUALITY CONTROL

8. The Future of Stainless Steel Coils: Sustainability

The industry is moving toward “Green Stainless Steel.” Since stainless steel is 100% recyclable, sourcing from mills that utilize scrap metal and renewable energy is becoming a priority for global brands. At GENNHANN, we support sustainable sourcing practices to help our clients meet their ESG goals.

9. Why Partner with GENNHANN STAINLESS STEEL ?

Navigating the stainless steel market requires more than just a vendor; it requires a partner who understands the technicalities of the material and the volatility of the market.

- Diverse Inventory: From 0.10mm thin strips to 6.00mm heavy-duty coils.

- Customized Solutions: Tailored slitting and surface treatments.

- Global Export Expertise: Years of experience serving clients in Southeast Asia, the Middle East, and beyond.

Technical Support: Our sales specialists, like Jian Han, are here to guide you from material selection to final delivery.

10. Frequently Asked Questions (FAQ) About Stainless Steel Coils

To help you with your procurement process, we’ve compiled the most common questions our clients ask.

Q1: What is the Minimum Order Quantity (MOQ) for stainless steel coils?

A: At GENNHANN STAINLESS STEEL we offer flexible MOQ options. For standard stock items like 304 2B or 316L No.1, we can often supply as little as one full coil or even slit strips. For custom production or special alloys, the MOQ may vary based on mill requirements.

Q2: Can you provide Mill Test Certificates (MTC) for every shipment?

A: Yes, absolutely. Every shipment is accompanied by a genuine MTC (EN 10204 3.1). This document verifies the chemical composition and mechanical properties, ensuring the material meets international standards like ASTM or JIS.

Q3: What is the difference between Mill Edge and Slit Edge?

A: * Mill Edge: The natural, slightly uneven edge of the coil as it comes from the rolling mill.

- Slit Edge: A clean, precisely trimmed edge created by our slitting machines. Slit edges are recommended for automated production lines requiring high width precision.

Q4: How do you protect the coil surface during international shipping?

A: We use robust Export Sea-worthy Packaging. This includes wrapping the coil in waterproof paper and a metal outer shell, secured with high-strength steel strapping. We also offer Eye-to-Sky or Eye-to-Wall palletizing to match your warehouse unloading capabilities.

Q5: Do you offer customized thickness and width?

A: Yes. We specialize in Precision Slitting and Cut-to-Length services. We can process wide mother coils into narrow strips with a width tolerance of ±0.1mm, tailored specifically to your stamping or forming equipment.

Conclusion: Ready to Source High-Quality Coils?

- Choosing the right stainless steel coil is a strategic investment. By focusing on grade suitability, surface quality, and supplier reliability, you ensure the longevity of your products and the efficiency of your production line.

- Looking for a competitive quote on Stainless Steel Coils? Contact GENNHANN STAINLESS STEEL Our team is ready to provide you with the latest market insights and the best material solutions tailored to your needs.

Recommended Internal Links

304 vs 316 stainless steel – What is the Difference