Table of Contents

In the high-stakes world of industrial manufacturing, the raw material is the foundation of your reputation. For procurement managers and engineers, choosing a stainless steel distributor is not just about comparing prices per ton; it is an exercise in Risk Management.

A delayed shipment can halt a production line. A batch of steel with inconsistent chemical composition can lead to catastrophic product failures in the field. Slight deviations in thickness tolerance can jam automated stamping machinery.

At GennHann Stainless Steel, we understand that you aren’t just buying stainless steel coils, sheets, or strips—you are buying predictability, stability, and peace of mind.

Established in 1980, GennHann has spent over 40 years perfecting the art of stainless steel processing and distribution. As a TOYOTA-certified factory and an ISO 9001 holder, we bridge the gap between global steel mills and your production line, ensuring that every micron of material meets the rigorous demands of modern industry.

The GennHann Standard: Why Top Manufacturers Choose Us

In a market flooded with traders and stockists, why do industry leaders entrust their supply chain to GennHann? The answer lies in our unwavering commitment to quality control standards that exceed general market expectations.

The TOYOTA Certification: A Badge of Operational Excellence

GennHann is one of the few distributors to have passed the rigorous factory audit by TOYOTA. In the manufacturing world, TOYOTA is synonymous with the highest standards of quality management and lean production.

This certification is not merely a plaque on the wall; it is proof that our operational processes—from material intake and storage to processing and delivery—adhere to strict protocols that minimize error and maximize consistency. When you source from a Toyota-certified partner, you are integrating Zero-Defect thinking into your own supply chain.

Over 40 Years of Industry Experience (Since 1980)

We have navigated through four decades of market fluctuations, raw material shortages, and technological shifts. This longevity translates into deep relationships with major global steel mills and a robust financial structure. While smaller traders may struggle during supply crunches, GennHann maintains stable inventory levels of 304, 304L, 316L, 430, and other key grades, ensuring your production never stops.

Precision Processing: Turning Raw Coils into Production-Ready Material

A master coil from a steel mill is rarely ready for immediate use. It requires precise customization. GennHann invests heavily in state-of-the-art European machinery to deliver material that integrates seamlessly into your automated lines.

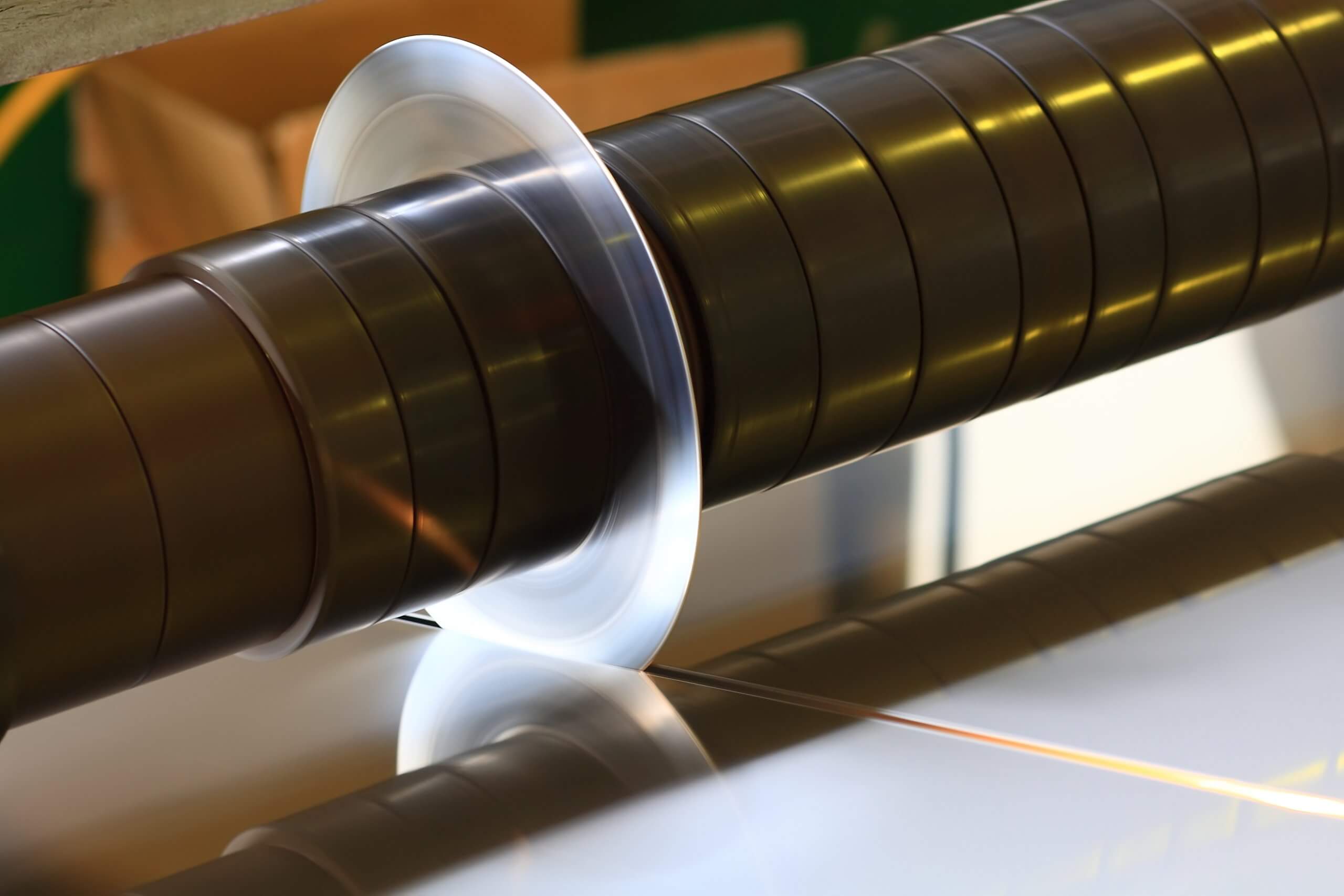

Precision Slitting: The Art of Tolerance

For manufacturers producing automotive components, electronic connectors, or medical devices, width tolerance is critical. Standard market tolerances are often insufficient for high-speed stamping molds.

GennHann utilizes advanced Rotary Shear Slitting Lines capable of processing stainless steel strips with exceptional precision.

- Minimizing Burr : Our tooling setup and blade maintenance protocols ensure minimal burr formation, protecting your dies and molds from premature wear.

- Camber Control: We strictly control the camber (edge bow) of the strip, ensuring smooth feeding into your continuous press machines.

- Tight Tolerances: We can achieve width tolerances significantly tighter than standard ASTM requirements, tailored to your specific engineering needs.

Surface Perfection: Italian IMEAS Polishing Technology

Aesthetic appeal is non-negotiable for appliances, architectural cladding, and food processing equipment. To achieve the perfect finish, GennHann employs the world-renowned Italian IMEAS polishing and grinding system.

Unlike basic domestic grinding machines that often leave chatter marks or uneven grain depth, the IMEAS system delivers:

- Uniform Consistency: Whether it is a No.4 (Brushed) or HL (Hairline) finish, the grain structure is consistent across the entire width and length of the sheet.

- Batch-to-Batch Reproducibility: If you order a batch today and another in six months, the surface finish will match perfectly—crucial for maintaining your brand’s visual identity.

- Enhanced Corrosion Resistance: Proper polishing not only looks good but also smoothes out microscopic crevices where contaminants could accumulate, thereby improving the material’s sanitary properties.

Material Authority: Understanding Grades and Standards

As a technical consultant to our clients, we ensure you select the exact grade required for your application. We strictly adhere to ASTM A240, JIS G4304/4305, and EN standards.

The Austenitic Workhorses: 304 vs. 316L

The most common question we receive from engineers is: “Do I really need 316L, or is 304 sufficient?” The decision impacts both cost and longevity.

304 / 304L Stainless Steel (18-8)

- Composition: Approximately 18% Chromium and 8% Nickel.

- Characteristics: Excellent formability and good corrosion resistance in normal atmospheric conditions.

- Typical Applications: Kitchen equipment, indoor architecture, storage tanks, and automotive trim.

- The “L” Advantage: 304L has lower Carbon content (<0.03%), which prevents carbide precipitation during welding. If your process involves heavy welding, 304L is essential to prevent intergranular corrosion.

316L Stainless Steel (Marine Grade)

- Composition: Adds 2-3% Molybdenum (Mo) to the Cr-Ni matrix.

- The Molybdenum Factor: This is the key differentiator. Molybdenum drastically increases resistance to pitting and crevice corrosion, particularly in chloride-rich environments (coastal areas, de-icing salts) or acidic chemical processing.

- Typical Applications: Marine hardware, pharmaceutical equipment, chemical processing plants, and outdoor architectural facades in aggressive climates.

430 Stainless Steel (Ferritic)

- Composition: High Chromium, no Nickel.

- Characteristics: Magnetic, good resistance to nitric acid, but lower general corrosion resistance than 300 series.

- Cost-Benefit: A cost-effective solution for indoor applications where high corrosion resistance is not the primary concern, such as dishwasher linings or magnetic boards.

Grade | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Best For |

304 | 18.0 – 20.0% | 8.0 – 10.5% | – | General Purpose, Indoor, Food |

316L | 16.0 – 18.0% | 10.0 – 14.0% | 2.0 – 3.0% | Marine, Chemical, Outdoor |

430 | 16.0 – 18.0% | < 0.75% | – | Indoor, Magnetic Applications |

Supply Chain Security: ERP and Logistics

In the B2B sector, a product is only as good as its delivery. GennHann integrates advanced ERP (Enterprise Resource Planning) systems to manage inventory visibility in real-time.

Just-In-Time (JIT) Delivery

We understand that modern factories operate on lean principles. We can work with you to establish rolling forecasts and safety stock agreements, ensuring that stainless steel coils and sheets are delivered exactly when you need them, reducing your warehousing costs.

Export-Grade Packaging

Steel is heavy and susceptible to moisture damage during ocean transit. We take zero risks with packaging:

- Waterproof Protection: All export materials are wrapped in high-quality waterproof paper and plastic film.

- Sturdy Skids: We use reinforced wooden pallets and skids designed to withstand the rigors of forklifts and crane handling.

- Edge Protection: Steel edge guards are applied to coils and sheet stacks to prevent mechanical damage to the edges—critical for material that will undergo automated feeding.

FAQ: Common Questions from Procurement Managers

Q1: How do you guarantee the chemical composition of your stainless steel?

A: Authenticity is our baseline. Every shipment from GennHann is accompanied by a Mill Test Certificate (MTC) from the original steel mill. This document details the exact chemical analysis (Heat No.) and mechanical properties (Yield Strength, Tensile Strength, Elongation) of the material. We ensure full traceability back to the furnace.

Q2: What is the difference between “Slitting” and “Shearing”?

A:

- Slitting: Cutting a large master coil lengthwise into narrower strips (coils). This is used for continuous stamping or roll forming lines.

- Shearing (Cut-to-Length): Cutting a coil crosswise into flat sheets or plates of specific lengths.

GennHann offers both services in-house with high precision.

Q3: Can you handle “Urgent Orders” or spot requirements?

A: Yes. Thanks to our extensive inventory of standard grades (304, 316L, 430) and sizes, we can often process and dispatch orders much faster than mill-direct lead times. Our “Spot Supply” capability is designed to help you handle unexpected spikes in demand.

Q4: Do you offer PVC film protection for polished surfaces?

A: Absolutely. For polished finishes like No.4, HL, or BA (Bright Annealed), we apply high-quality PVC or PE laser-film (Fiber or CO2 laser compatible) to protect the surface during your fabrication process (bending, punching, laser cutting).

Conclusion: Your Strategic Partner in Manufacturing

In an industry filled with variables, GennHann Stainless Steel is your constant.

We don’t just supply metal; we supply manufacturing continuity. Whether you need the aesthetic perfection of Italian-polished sheets or the microscopic precision of slit strips for electronic components, our 40 years of experience and Toyota-certified processes are at your disposal.

Stop worrying about material risks and start focusing on your production growth.

Ready to secure your supply chain?

Contact our technical sales team today for a consultation and a competitive quote. Let GennHann be the backbone of your manufacturing success.

🌐 Website: www.ghinox.com

📧 Email: info@ghinox.com