Table of Contents

Introduction

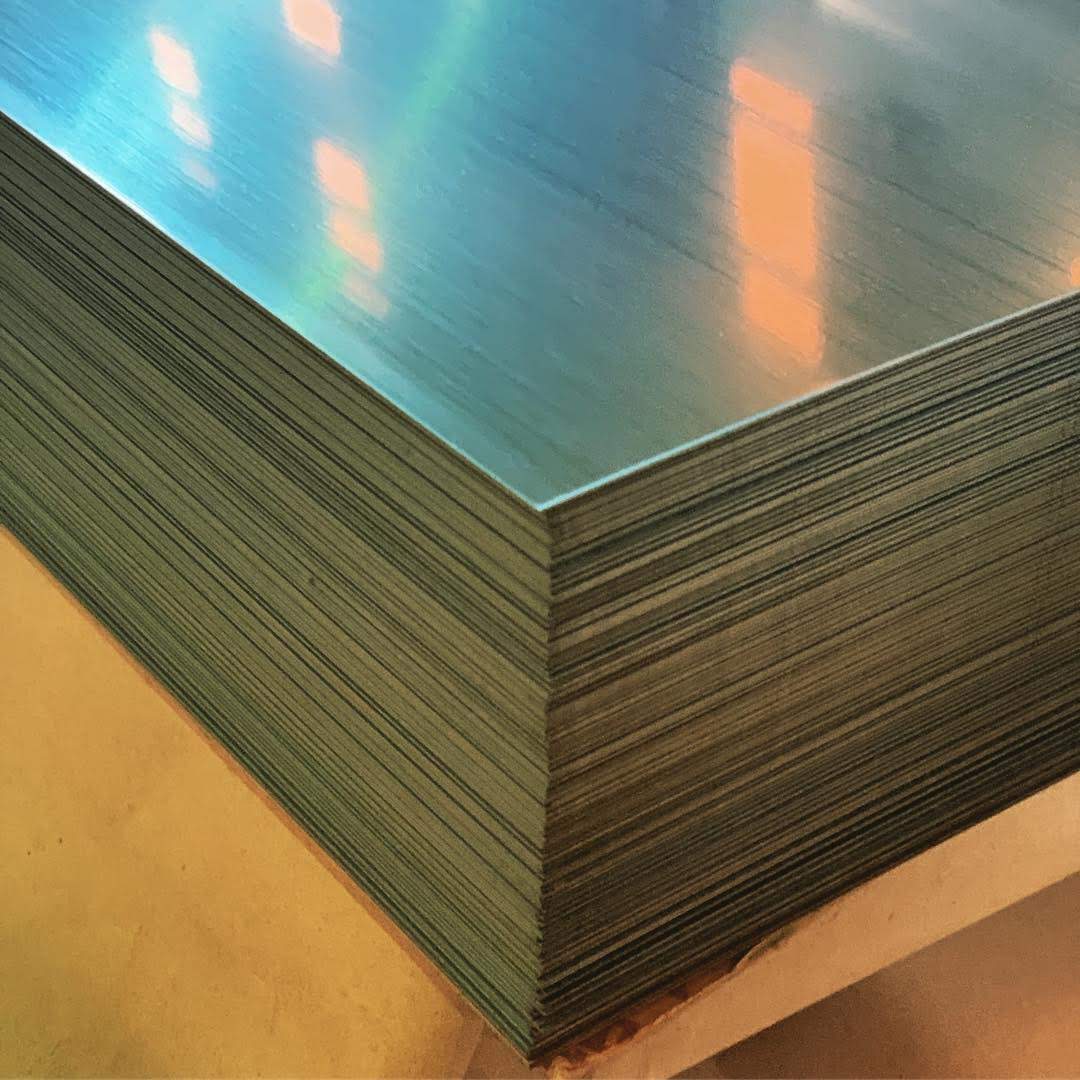

Stainless steel is widely recognized for its durability, corrosion resistance, and aesthetic appeal. However, during manufacturing, transportation, processing, and installation, stainless steel products are vulnerable to scratches, stains, oxidation, or damage. This is especially true for mirror-finish stainless steel and brushed stainless steel sheets, where even minor flaws can reduce the product’s value.

To solve this problem, manufacturers commonly apply a stainless steel protective film—a thin yet essential layer that acts as an invisible shield. Though simple in appearance, protective film is critical for maintaining surface quality, ensuring smooth processing, and delivering a flawless product to end-users.

Why Do Stainless Steel Products Require Protective Film?

Based on industry insights, protective film serves four main functions:

Function | Description | Example |

Scratch Prevention | Prevents scratches during stacking, transportation, or handling. | Stainless steel doors, elevator panels. |

Facilitates Processing | Protects surfaces during laser cutting, bending, or stamping. | CNC sheet processing |

Preserves Appearance | Keeps stainless steel bright, clean, and fingerprint-free until installation. | Mirror stainless steel, colored coils. |

Identification & Labeling | Printed films help distinguish grades, specifications, or usage. | Quick recognition of 304 vs 430 stainless steel. |

👉 Simply put, protective film doesn’t enhance performance—it preserves value. Similar to a smartphone screen protector, it ensures the surface stays pristine.

Which Stainless Steel Products Typically Use Protective Film?

Not every stainless steel sheet requires film. Industrial sheets for internal structures may not need surface protection. However, the following products almost always use protective film:

- Decorative Stainless Steel – building façades, elevator panels, handrails, interior design.

- Food-Grade Stainless Steel – kitchen countertops, refrigerator doors, water dispensers.

- Precision Processing Sheets – thin sheets requiring laser cutting or bending.

- Mirror and Brushed Finishes – highly polished surfaces where scratches are unacceptable.

👉 Example:

- Mirror 8K sheets must always be protected during storage and transport to avoid visible scratches.

- Laser-cut stainless steel sheets require specialized protective film to withstand heat and mechanical stress.

Key Considerations When Applying Protective Film

Industry experts emphasize that protective film application must follow specific standards:

- Uniform Thickness – prevents peeling or uneven performance during processing.

- No Air Bubbles – trapped air may cause oxidation or burn marks during cutting.

- Heat and Tear Resistance – films must withstand laser cutting and bending without melting or detaching.

- Timely Removal – after installation, the film should be removed promptly to prevent adhesive residue.

Common Issues and Practical Cases

- Why does protective film on stainless steel railings sometimes become difficult to remove?

→ Because it wasn’t removed in time. Sunlight and heat cause adhesives to harden. The solution is to use specialized cleaning agents, not sharp tools that may scratch the surface. - Why is protective film essential for mirror finishes but not always for industrial stainless steel?

→ Mirror stainless steel undergoes multiple polishing processes, making scratches highly visible, while industrial-grade sheets are less appearance-sensitive. - Does protective film affect laser cutting?

→ Yes. Low-quality films may cause issues such as slag, incomplete cutting, or high-reflection alarms. Therefore, specialized laser-cutting films are required.

Conclusion

“Protective film for stainless steel is not about changing the product, but about preserving its integrity and value. It prevents scratches, maintains surface aesthetics, and ensures reliable processing throughout manufacturing and installation. For mirror-finish, brushed, and food-grade stainless steel, applying protective film is an industry standard that guarantees customer satisfaction and longer product lifespan.”